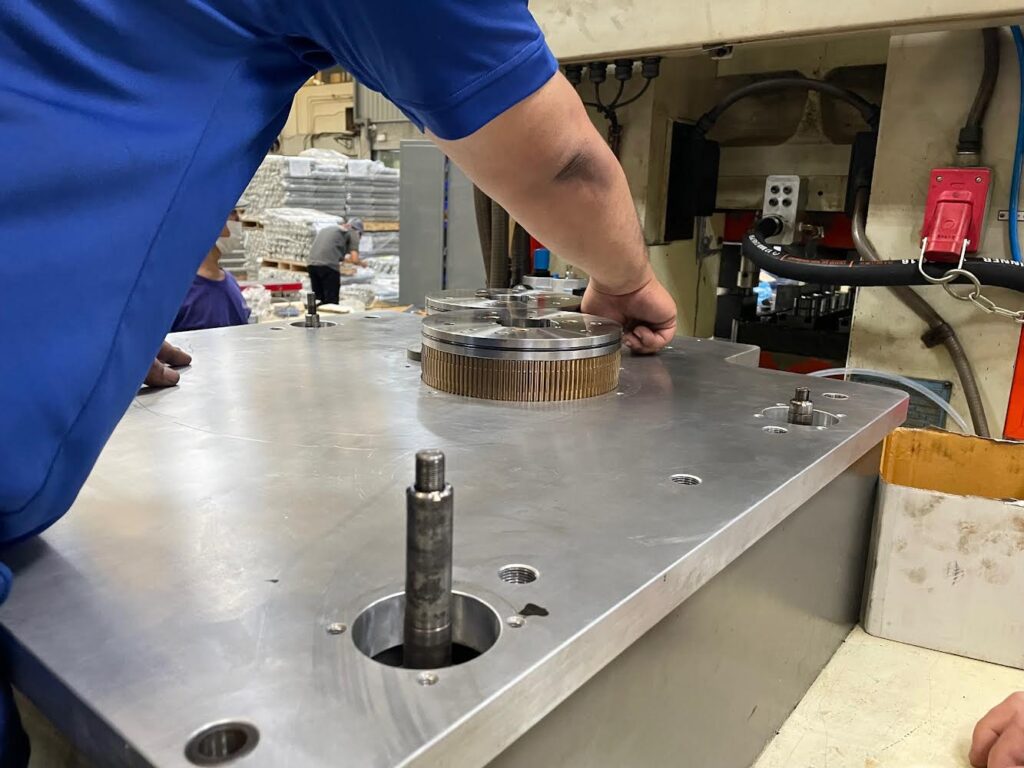

We can supply carbide and steel tab and end tooling, as well as press components with the same quality as the original manufacture. We can design and build fully customized new or reconditioned conversion systems utilizing Minster, Bruderer or Brown and Boggs Presses.

01 CONVERSION PRESS SYSTEM

We offer in-plant training for all Conversion System related assemblies and operations. Some topic include Tab Die and Lane Tooling Maintenance, Main Die Removal and Re-installation, and the maintenance of the entire transfer system.

For all Steel and Rubber Belt Systems we will present information on Downstacker Timing, Belt Alignment and Vacuum Box Timing that will help keep the system running at maximum output with minimal down time.

Buhrke style Transfer Bar Systems require special knowledge of an entirely different timing profile for a Conversion Press. We can provide training in all aspects of Transfer Bar Press System function and maintenance.

For all Conversion Systems, We offer training in resetting the ram and the tooling after stop block replacement or to minimize the tonnage load for accurate production.

We can assist with the Service tool, Buhrke/Quantum, Stollen or SLAC Conversion Presses.

Working with your press operators and personnel.We will find and fix the chronic problems that limit your production goals. We will provide the solutions that will best serve your future productions needs.

Available engineering services include new product designs, improvement and customization to existing assemblies, and designed solution to solve chronic problem with existing systems.

Spare part back-engineering service are available to provide properly tolerance detail part drawing for your stocked OEM parts that have no reference. We can make new drawings or review and advise the customers engineers with their in-house engineering to bring it to OEM standards.

3 Steps of Engineering Services

3 Steps of Engineering Services

04 NEW DESIGN SERVICES

We specifically focus on the Easy Open End manufacturing including tab and end tooling.

We specifically focus on the Easy Open End manufacturing including tab & end tooling.